There is always a process in every organization that drives everyone crazy. The steps in the process are always delayed and error-prone. You try to make things faster and efficient, but it’s not easy because the process is crucial to many employees.

Six Sigma, lean management, and total quality management are highly regarded process improvement methods. But they’re impractical for processes that are neither too complex nor too simple. It is too much work to implement such methodologies for processes like budget approvals and purchase requests when you’re not a logistics-based company.

A process can always be made efficient with simple changes. Work culture and the tools employees use are the main factors that influence the efficiency of a process. Instead of plugging holes all the time, you can prevent the holes by making these changes to your process.

1. Make documentation accessible to everyone

Employees who are responsible for the process should definitely have access to the process documentation. If the employees who carry out the steps of the process only know their own responsibilities, you can never drive the process to efficiency. Employees just assume their step is the most important and ignore everything else.

The employees involved in the process are the best people to improve it. Share the documentation and make it accessible to everyone. Make sure they understand every nook and corner of the process. Slowly, you will notice employees making suggestions on how the process can be improved.

2. Prioritize tasks and assign stakeholders

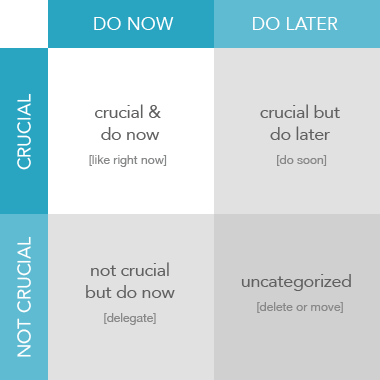

Instead of trying to chase every request in the process, prioritize them and bring out the best quality. Steven Covey’s prioritization matrix can help here.

Source:https://appfluence.com/productivity/prioritization-matrix

You can model the matrix to fit into your process execution strategy. Define conditions for when an item is crucial and not-crucial.

Let’s say you have a sales order process. You could prioritize the orders factoring in customer lifetime value (CLV), level of urgency, and size of the order. You can assign conditions for when an order is high-priority when the metrics collectively cross a certain threshold value.

3. Automate the process

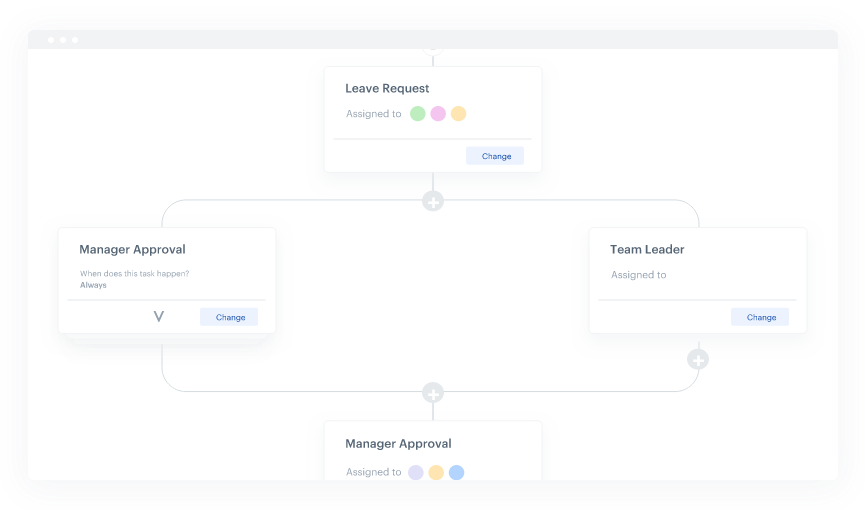

Automation works based on preset rules and conditions. To automate a process, everyone is required to understand the process clearly. All the manual emails and request routing are completely automated. The items in the process reach the right people based on the conditions specified in the documentation.

With Kissflow Process you can automate any process easily in a matter of 15 minutes. The intuitive interface makes it easy for anyone to build and make changes to a process with ease. Instead of relying on IT or technical help, you can manage the process yourself with complete control.

4. Encourage proactive communication

A lot of errors can be prevented by proactive communication. If an employee foresees an error or inefficiency in the process, coworkers should realize the impact and act on it quickly. Nurture a work culture that encourages team members to identify and solve problems. Announce incentives to employees for increasing the efficiency of the process.

Proactive communication does not mean restlessly seeking problems and solving them. It is acting on a problem immediately after you identify one.

5. Monitor the process at regular intervals

Assign a process owner if there isn’t one. The process owner is responsible for supervising and maintaining good function of the process. Usually, the process owner is the department head or someone who has clearance to access all data within the process.

Choose regular time intervals after which the process owner analyzes the process. The process should have completed enough cycles to give you enough data on how it has performed. See if all the steps are working at their best efficiency. Identify patterns of errors in the process and find out ways to eliminate them.

6. Make changes that bring maximum impact

There are hundreds of improvements you can make to the process. But everything cannot be done in one shot. Be smart at choosing which improvements to execute. The Pareto principle comes in handy.

The pareto principle states that 80% of the consequences come from 20% of the causes. It also means that if you act on 20% of the causes you bring 80% improvement. Instead of doing pointless busy work, concentrate on making improvements that bring more impact.

You need not break your head calculating the percentage of impact. Remember and apply the principle theoretically when you have multiple improvements to make.

Final thoughts

No workplace operates at a hundred percent efficiency. It’s normal to have chaotic processes that induce confusion and chaos. But you make the difference by acting on it and optimizing the process constantly. That is what separates the average from the best.

All these tips are equally important to make a continuous improvement in your process. Execute these changes and reduce the inefficiencies in your chaotic process.