The lean methodology originates from Toyota’s manufacturing unit but it slowly became apparent that project managers can use lean principles to reduce wastes and inefficiencies in any industry. From healthcare to software development, principles of lean are helping managers cut their costs and keep a competitive edge.

For many American companies, being lean is the only way for them to compete on the global level against competitors from countries where the production costs are significantly lower.

What is lean?

Lean is often referred to as ‘rigorous elimination of waste’ due to the methodology’s focus on creating the most efficient environment that fosters growth. To implement lean project management in any team, the manager must follow the three pillars of lean. The three pillars are to spotting wastes, stimulating improvements daily, and recording those improvements.

Implementing lean in any environment is an iterative process that helps you identify areas where no value is added to your product. To be completely free of waste, a process must go through lean multiple times.

Another thing that makes lean great is its adaptability. It has a track record of working in several different industries and in project management, the methodology even grows with the industry. With the whole world adopting IoT and Industry 4.0, lean is becoming data-driven. It is growing with the industry to keep on delivering exceptional value to the customers.

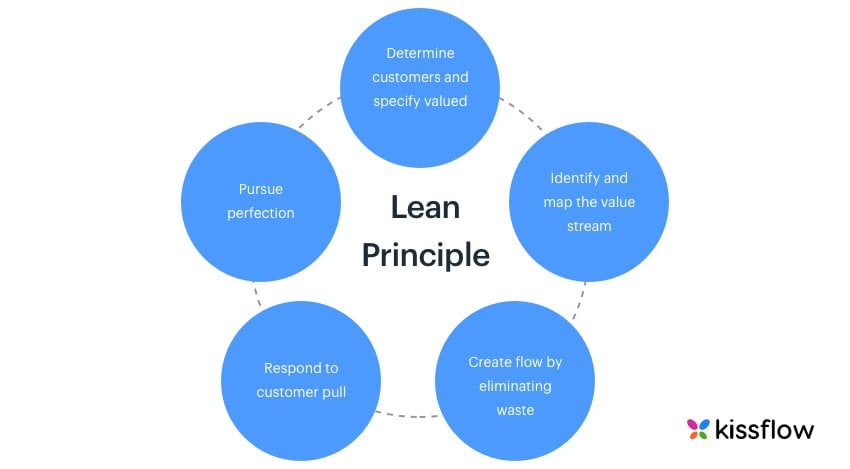

5 principles of lean explained

First described by the founders of Lean Enterprise Institute in 1997, the principles of lean act as a building block on which the entire methodology stands. In the project management book “The Machine that Changed the World,” Womack and Jones described the five principles of lean as the ultimate recipe to improve the efficiency of a workplace.

1. Identify value

The first lean principle is all about identifying the needs and requirements of the customers. It important for managers to evaluate the actual needs of their customers by conducting detailed interviews and analysis. Identification of value is especially important in the case of novel products.

Customers usually are not articulate enough to get their complete requirements across and managers are responsible for keeping the customers engaged and understand their expectations.

And don’t forget to try our Free and Customizable Templates:

– Content Calendar Template for Strategic Content Planning

– Competitive Analysis Template for Strategic Content Planning

2. Map the value stream

Identification of all the activities required to complete the project successfully is defined as the value stream. This is the second step of lean project management that uses the values identified in the first step as a reference point.

By properly mapping the entire value stream, managers can identify areas of inefficiencies and work on eliminating them. This helps project teams deliver the best value to the customer and save the company’s resources to maximize profits.

3. Create a flow

After the wastes of lean have been removed, a workflow has to be created for smoother implementation of the project. The entire project management process gets divided into independent delivery units or milestones that occur sequentially until the end of the process.

To avoid any bottlenecks and unexpected delays in the project, it’s important to ensure that each event of the value stream takes place without any friction and all the required resources are available on time.

Here is our Customizable Marketing Templates to try for Free:

– Marketing Plan Template to Streamline your Marketing Efforts

– Social Media Calendar Template for Social Media Planning

4. Establish pull

Maintaining an inventory is extremely important for any process and you can’t waste time waiting for the required resources or material to arrive after each milestone. However, maintaining excess inventory means increased costs and more waste. The fourth lean principle majorly deals with two major sources of wastes and values in lean inventory and work in progress.

By establishing a pull and ensuring nothing is processed or made ahead of time, the costs of maintaining inventory can be reduced significantly. The term ‘just in time’ comes from this approach and negates the traditional approach of relying on forecasts and approved schedules.

5. Continuous improvement

The final principle of lean project management is the uncompromising and endless pursuit of perfection. By improving iteratively and learning from their shortcoming each time, managers ensure that their teams would perform significantly better in the future.

Tired of using Wrike?

See why Wrike is not efficient to manage projects and why you need a Wrike Alternative.

Implementing lean principles in your project

Implementing lean properly is a surefire way of getting ahead of the curve in today’s competitive industrial environment. Following lean principles can significantly reduce the cycle times, inefficiencies, and associated costs.

As a manager, you need to understand that effective communication throughout the process is necessary for this approach to succeed. Fortunately, multiple project management tools on the internet can make your job easier.

A cloud-based project management software can be accessed from anywhere on multiple platforms. On the Kissflow project, you can get assign tasks, customize project management templates, track progress, and do much more to ensure your team performs at their best. Click here to sign up and try Kissflow Project for free.